DARPA and US Department of Defense does NOT endorse this post or project idea.

Here is a DARPA project idea (more about DARPA) to develop a quick, simple, scalable system to grow kelp and to increase the number of useable products kelp can produce.

Kelp Loop Introduction

Project Kelp Loop is an innovative initiative modeled after the RepRap 3D printing project, with a focus on sustainability and environmental regeneration. This project aims to develop a self-sustaining cycle where kelp, a fast-growing seaweed, is cultivated extensively and then processed into a versatile building material. The primary objective is to create a closed-loop system where the material derived from harvested kelp can be used not only for food, fuel, or general construction purposes but also to expand the project’s own production facilities.

What are you trying to do? Articulate your objectives using absolutely no jargon.

Create a module system to grow kelp that is built out of material made from kelp. Similar to the RepRap 3D printing project, a 3D printer that could replicate itself and use Polylactic acid, PLA (plastic that can be derived from plants). Kelp would be grown in the ocean, harvested, then processed into usable material.

How is it done today, and what are the limits of current practice?

Ocean based production of materials is a cottage industry, that is not scaled. One method to addressing climate change is going kelp or algae, however humans would need to quickly scale this to make an impact on human contributed legacy carbon.

What is new in your approach and why do you think it will be successful?

The Kelp Loop project introduces an innovative approach to sustainable material production by harnessing the rapid growth and renewable nature of kelp. Unlike traditional methods that heavily rely on terrestrial resources, this project utilizes kelp to create a variety of eco-friendly building materials, such as bio-composites, insulation panels, and structural elements.

What sets Kelp Loop apart is its development of a closed-loop system that not only produces materials from kelp but also uses these materials to enhance and expand production capabilities. This approach maximizes the environmental benefits of kelp, such as carbon sequestration, and minimizes ecological impacts compared to land-based resource extraction.

Success is anticipated due to several factors:

- Renewable Resource Utilization: Kelp is a fast-growing seaweed that does not require arable land, freshwater, or fertilizers, making it an ideal resource for sustainable production.

- Advanced Bioprocessing Techniques: The project is poised to leverage recent advancements in bioprocessing and genetic engineering to optimize the growth and material properties of kelp, ensuring high yields of convertible biomass.

- Environmental and Economic Benefits: By reducing reliance on depleting terrestrial resources and minimizing ecological disruption, Kelp Loop supports environmental sustainability while potentially lowering material costs.

- Regulatory Alignment and Ecological Management: With an approach designed to align with regulatory frameworks and ecological management practices, the project mitigates potential environmental and regulatory risks.

Who cares? If you are successful, what difference will it make?

The Kelp Loop project has the potential to significantly impact various stakeholders, particularly the US military, and aligns closely with the Department of Defense’s (DoD) strategic objectives as outlined in the 2022 Climate Adaptation Plan.

Impact on the US Military:

- Rapidly Deployable Infrastructure: The materials produced by Kelp Loop can be used to quickly construct military bases and other infrastructures, especially in remote or environmentally sensitive areas. This capability enhances the military’s operational flexibility and rapid response in various global scenarios.

- Sustainability and Self-Sufficiency: By enabling the production of building materials on-site, Kelp Loop reduces logistical footprints and supports military operations in conflict or disaster-impacted regions, promoting greater self-sufficiency.

- Environmental Stewardship: The project supports the DoD’s commitment to environmental sustainability. By utilizing eco-friendly materials, the military can reduce its environmental impact while setting a precedent for sustainable practices within the defense sector.

- Innovative Solutions: Kelp Loop’s development of new materials could lead to further innovations that may be applicable to other military technologies and logistics, enhancing overall operational capabilities.

Alignment with DoD Objectives: According to the Department of Defense’s 2022 report, there is a concerted effort to “leverage purchasing power to spur innovation and deployment of climate adaptation and mitigation technologies” (Department of Defense, 2022). Kelp Loop contributes directly to these goals by creating a renewable supply chain for building materials derived from kelp, thereby supporting the DoD’s broader climate goals and national security objectives.

Broader Societal Impact:

- Potential as Food Source: Beyond building materials, kelp is a nutritious food source. Expanding its use in the food industry involves developing safe and palatable kelp-based products, which could provide sustainable and healthy food options.

- Biofuel Production: Kelp Loop’s extension into biofuel production aligns with the DoD’s interest in improving energy storage supply chains. Kelp-based biofuels could offer a sustainable alternative to traditional fuels, supporting energy security and reducing dependence on foreign oil.

What are the risks?

The Kelp Loop project, if initiated as a DARPA-funded initiative, entails several risks that could impact its execution and success:

Technological and Developmental Risks:

The technology required to convert kelp into viable building materials and biofuels is still in its developmental stages. Significant advancements in bioprocessing, genetic engineering for enhanced biomass yields, and harvesting technologies are crucial to achieve economic and operational feasibility.

Economic Viability:

The process of transforming kelp into biofuels and building materials must be cost-effective. Balancing the input of energy and resources against the output is essential to ensure the economic sustainability of the project. High development costs and the uncertainty of market acceptance pose substantial financial risks.

Environmental and Ecological Concerns:

Scaling up kelp farming could lead to unintended consequences for marine ecosystems, such as habitat disruption and species displacement. Extensive kelp removal might also affect marine biodiversity and water quality, requiring careful management to mitigate negative impacts.

Regulatory and Compliance Challenges:

There are potential regulatory hurdles related to the use of novel materials and techniques, especially those involving genetically modified organisms or new bioprocessing methods. Gaining regulatory approval and public acceptance, particularly concerning environmental impact and safety, is essential but can be complex and time-consuming.

Scalability and Infrastructure:

Transitioning from pilot-scale to industrial-scale production can be challenging. Developing large-scale aquaculture systems and processing facilities that are both economically viable and environmentally sustainable is critical but fraught with technical and logistical difficulties.

Climate Dependency:

The growth of kelp is highly sensitive to environmental conditions such as water temperature, salinity, and nutrient levels. Climate change and variability in oceanic conditions could adversely affect kelp yield, impacting the project’s stability and predictability.

Integration with Existing Systems:

Incorporating kelp-based materials into existing construction practices and standards may require significant modifications to current building techniques, training for workers, and updates to building codes, which could slow down adoption and integration.

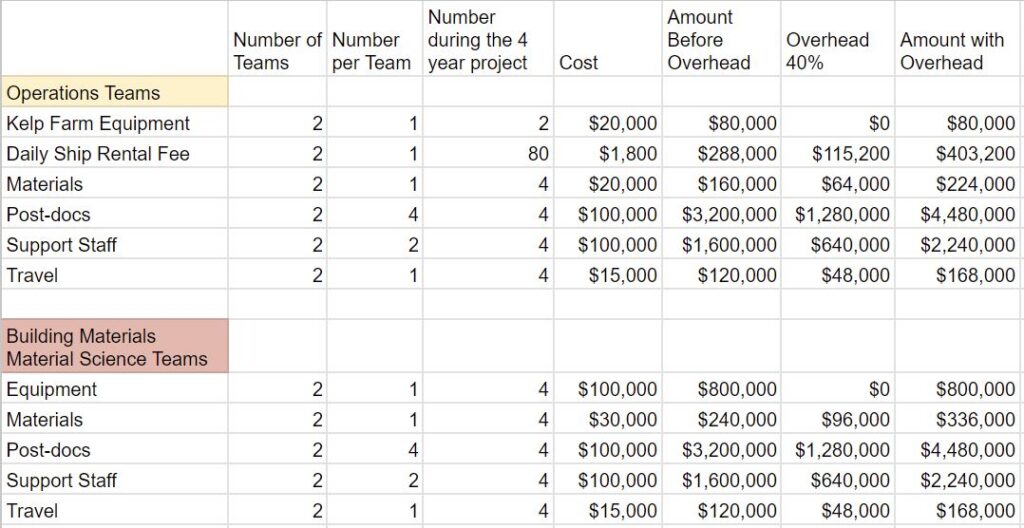

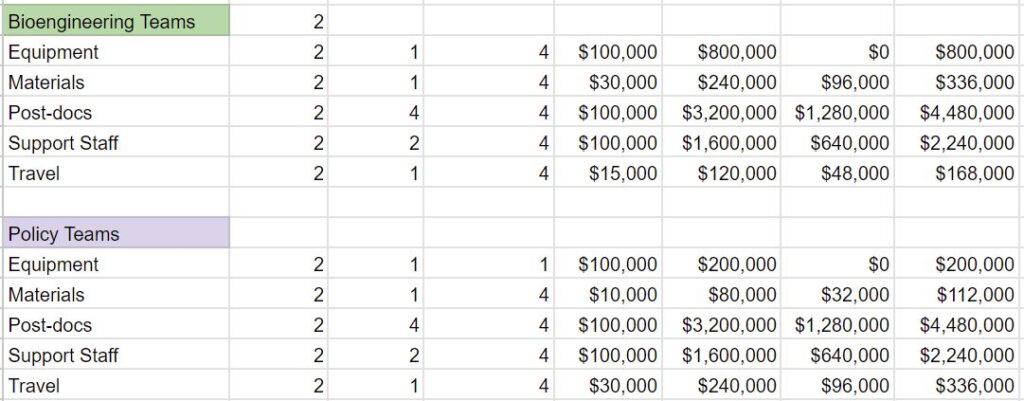

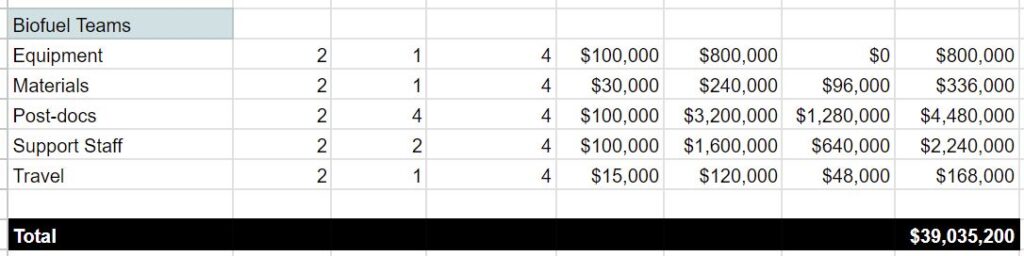

How much will it cost?

The project will have two teams for each innovation area: Operations, Material Science, Bioengineering, Policy, Biofuels. Each will have two teams incase something unexpected occurs that prevents one of the teams from being able to continue on the project. The total estimated costs is $36 Million.

Operations team

The operations team will focus on challenges of growing and scaling a kelp growing operation. Often in scaling agricultural product there are unforeseen issues they could be known or unknown issues. This team is to address known issues and discover unknown issues. Issues might include: kelp diseases, kelp pests, aquaculture weeds, equipment durability, and system maintance.

Material Science

The material science team is to further develop useable materials that can be derived from kelp. These materials will then be tested by the operations team.

Bioengineering Teams

The bioengineering team is investigate ways to increase the growing rate of kelp in a managed agricultural system.

Policy Team

The policy team is to help the other teams navigate regulatory huddles during the project and propose changes to streamline a process for rapid scaling of kelp farms in the United States exclusive economic zone. Work might include: permits for kelp farms at the federal, state, and local level, permitting of genetically engineered kelp, approval of kelp derived materials.

Biofuel Team

The biofuel team is to develop a biofuel derived from kelp that could be used in current US naval ships.

Possible locations

There will be two kelp farms each in a different location. Based on location and institutions near by these locations might be two of the following:

Monterey Bay, California

- Already supports large kelp forests

- Monterey Bay Aquarium Research Institute

- Stanford University’s Hopkins Marine Station

- Naval Postgraduate School in Monterey

Narragansett Bay, Rhode Island

- Atlantic environment with diverse marine environment

- Established fishing industry

- University of Rhode Island’s Graduate School of Oceanography

- The Naval Undersea Warfare Center

San Diego, California

- Established aquaculture industry

- Scripps Institution of Oceanography

- Naval Base San Diego

Below is the proposed budget.

How long will it take?

What are the mid-term and final “exams” to check for success?

The Kelp Loop project is designed to enhance the efficiency and scalability of kelp farming, simplifying the process, and developing valuable kelp-derived products. The project will be evaluated based on its ability to meet these objectives, specifically focusing on reducing the time required to establish kelp farms and the utility of the resulting kelp products.